Introduction

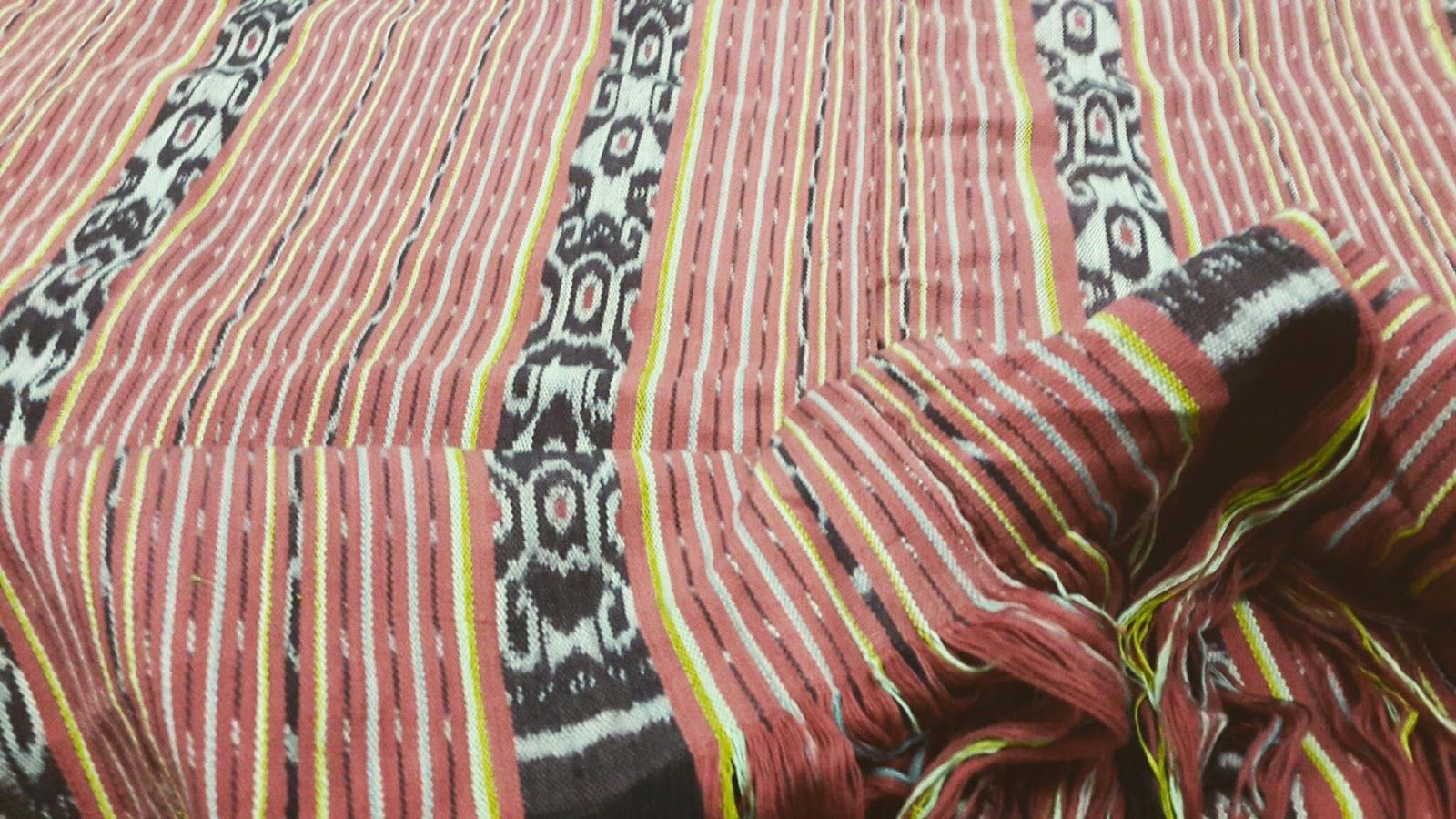

Kain Tenun NTT, also known as East Nusa Tenggara woven fabric, is a beautiful traditional textile that originates from the eastern part of Indonesia. This intricate fabric is highly regarded for its unique patterns and vibrant colors, making it a popular choice for clothing, accessories, and home decor. In this blog post, we will take a closer look at the fascinating process of how Kain Tenun NTT is made, from start to finish.

Gathering the Materials

The first step in creating Kain Tenun NTT is gathering the materials needed for weaving. The main material used is cotton yarn, which is sourced from local cotton plants. The cotton is carefully harvested and processed to create the yarn that will be used in the weaving process. Additionally, natural dyes are collected from various plants and minerals to add color to the fabric.

Designing the Patterns

Once the materials are ready, skilled artisans begin the process of designing the patterns for the Kain Tenun NTT. This is a highly intricate and time-consuming process that requires great attention to detail. The patterns are often inspired by nature, culture, and local traditions. The artisans use their creativity and expertise to create unique and visually stunning designs that will be woven into the fabric.

Setting up the Loom

After the patterns are finalized, the next step is setting up the loom. The loom is a device used to weave the fabric. It consists of a frame, which holds the threads in place, and various other components that allow the weaver to create the desired patterns. The threads are carefully arranged on the loom according to the design, and the warp and weft threads are separated.

Weaving the Fabric

With the loom set up, the weaving process can begin. The weaver carefully interlaces the weft threads through the warp threads, following the predetermined pattern. This requires great precision and skill, as any mistake can disrupt the design. The weaver uses a shuttle or a needle to pass the weft threads through the warp threads, creating the fabric one row at a time.

Adding the Colors

As the weaving progresses, the weaver adds colors to the fabric using the natural dyes collected earlier. This is done by dipping the weft threads into the dye baths and then weaving them into the fabric. The weaver carefully selects the colors and determines the placement of each color in the design, creating a harmonious and visually appealing composition.

Finishing Touches

Once the weaving is complete, the fabric undergoes several finishing processes to enhance its quality and durability. This includes washing, ironing, and sometimes adding additional decorative elements such as embroidery or tassels. These finishing touches add the final touches of beauty to the Kain Tenun NTT, making it ready to be used in various applications.

Preserving the Tradition

The process of making Kain Tenun NTT is not only a craft but also a cultural tradition that has been passed down through generations. It requires great skill, patience, and creativity. By supporting the artisans and purchasing Kain Tenun NTT products, we can help preserve this rich cultural heritage and ensure that this traditional craft continues to thrive for years to come.

Conclusion

The process of making Kain Tenun NTT is a labor of love that involves gathering materials, designing patterns, setting up the loom, weaving the fabric, adding colors, and applying finishing touches. Each step is carefully executed by skilled artisans who have mastered the art of traditional weaving. The result is a beautiful and unique fabric that reflects the rich cultural heritage of East Nusa Tenggara. By appreciating and supporting Kain Tenun NTT, we contribute to the preservation of this traditional craft and help sustain the livelihoods of the talented artisans behind it.

.jpg)

Tidak ada komentar:

Posting Komentar